Exterior fire spread discussed by Tim Veater.

http://thefader-res.cloudinary.com/images/w_760,c_limit,f_auto,q_auto:best/GettyImages-695781690_js5kch/police-man-a-security-cordon-as-a-fire-engulfs-the-grenfell-tower-in-west-london.jpg

Now let me deal with a number of issues in relation to the external spread of fire.

From the above photograph, taken probably less than half an hour after the fire erupted, certain features can be observed.

The fire has already reached to the top of the building on at least two exterior elevations, setting alight the interior rooms as it progressed. With reference to the above photograph, it would appear the surface cladding on the left hand elevation, where it is claimed the fire started within a fourth floor flat, at this point has in fact burnt out, leaving fires, within virtually all the flats on that elevation.

Live video of the event can be seen here: https://www.youtube.com/watch?v=mWwNvdTqb68&t=40s

https://az-eandt-live-media.azureedge.net/e/3/c/b/d/d/e3cbdd8718bb26e95a3b8bd200a525c487fd8896.jpeg

Meanwhile, fire still rages in a diagonal line of flame on the right hand elevation, setting alight to flats as it progressed. Significantly please note how this upward movement of flame appears to be contra-indicated on the far right. I would suggest that this is because it travelled down the corner vertical rib feature, suggesting no effective fire breaks had been incorporated in the design.

This conclusion is supported by the following image after the fire had been extinguished (below).

/https%3A%2F%2Fblueprint-api-production.s3.amazonaws.com%2Fuploads%2Fcard%2Fimage%2F510306%2Fa7b34ac5-1b27-42bd-a59a-fc73036ec899.jpg)

https://i.amz.mshcdn.com/8_eMVJ12bXvwU9H4O8gBxbgQBZM=/950x534/filters:quality(90)/https%3A%2F%2Fblueprint-api-production.s3.amazonaws.com%2Fuploads%2Fcard%2Fimage%2F510306%2Fa7b34ac5-1b27-42bd-a59a-fc73036ec899.jpg

Note how consistently there is evidence that fire has travelled down the vertical ribs beyond the face particularly in respect of the far right corner. Apparently in this manner fire traversed from just one side to all four! This is quite remarkable.

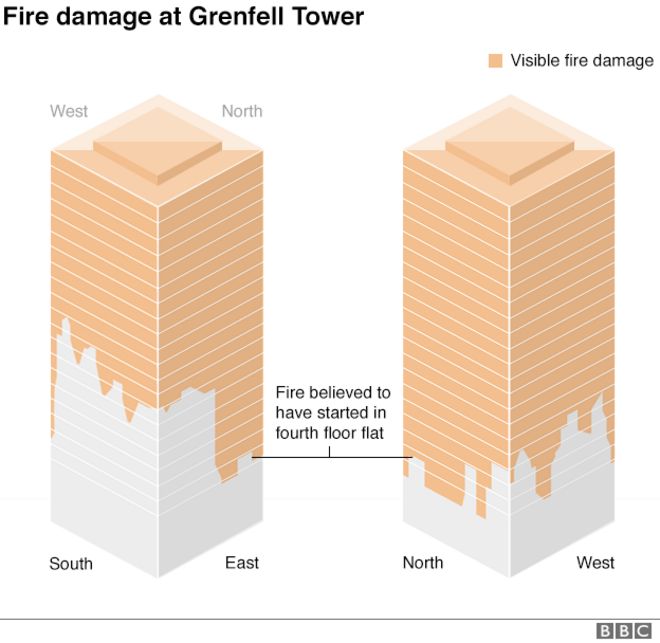

Plainly, not only was the cladding highly flammable, there were no effective fire stops either vertically or laterally. Indeed the material and design of the vertical ribs appears to have facilitated the spread upwards and downwards, and significantly around the corners of the building. The damage to the four elevations is represented in the following diagram:

https://ichef.bbci.co.uk/news/660/cpsprodpb/C942/production/_96522515_grenfell_tower_fire_starting_point_624.png

From the above BBC illustration it would appear from the initial fire location on the North East corner of the building, flame spread predominantly upwards in both directions, subsequently engulfing the South and West elevations also. It is also likely that wind direction played a significant part in the flame progression.

The above diagram is supported by this image of the still smoking tower block, facing the morning sun and so revealing the western and southern elevations to left and right.

https://1k95i3bqziq3bboq03r87f8x-wpengine.netdna-ssl.com/wp-content/uploads/2017/06/FIRE-Grenfell-072200-760x507.jpg

The fire was obviously hot enough to breach any barrier provided by the windows and set fire to flat interiors that were extensively damaged. Whether there were any other factors that supported the interior fires, awaits to be seen but there are some puzzling images of intense flame whist combustible items such as cupboards remain largely undamaged. This needs to be explained particularly in relation to possible gas supply.

Apart from the basic problem of inadequate fire stops, it is clear that the cladding itself demonstrated no evidence of fire resistance. Indeed it appears to have been highly flammable. It is quite astounding that such a material was specified and/or approved for such use, if indeed it was. Only a searching investigation, including the examination and testing of remaining panels, will determine this point.

It has been reported that the fire-resistant version would have added only £5,000 to the overall cost. In view of earlier incidents around the world and specific warnings, it is hard to view this decision as other than scandalously reckless!

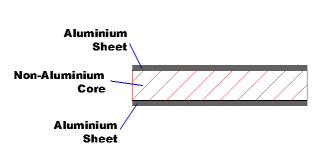

The exterior cladding, consists of a 3mm composite panel - a 'sandwich' of aluminium and polythene. (See diagrams above and below) The polyethylene is flammable, the aluminium is not. In a statement issued after the disaster at the end of last week, the Department for Communities clarified the legal position as follows:

“Cladding using a composite aluminium panel with a polyethylene core would be non-compliant with current Building Regulations guidance. This material should not be used as cladding on buildings over 18m in height.”

If this is the official government position, the question remains how it came to be used and escaped all the professional and administrative hurdles in the process?

Wikipedia states:

"In September 2014 a building regulation notice a for the recladding work was submitted to the authority, and marked with a status of "Completed—not approved". The use of a "Building Notice" building control application is used to remove the need to submit detailed plans and proposals to a building control inspector in advance, where the works performed will be approved by the inspector during the course of their construction. Building inspector Geoff Wilkinson remarked that this type of application is "wholly inappropriate for large complex buildings and should only be used on small, simple domestic buildings"" (4)

The obvious question to be answered by any enquiry therefore is:

- Why was the cladding specified and allowed to be used in this case?

- Did the architects specify it knowing it breached Building Regulations?

- Did the clients through their architects, seek Building Regulations approval or did it escape such oversight as a self-certification?

- Could it have happened if previous governments had not relaxed the planning/building regulations legal framework allowing developers to self-certify works of this nature?

- Or is there evidence that a cheaper material had been substituted from that specified?

The panels are made by an American firm, "Arconic". Its web page here (https://www.arconic.com/global/en/what-we-do/building-and-construction.asp) states:

"Arconic has been helping advance innovation in building design for well over a century. We invented the look of the modern downtown, and then, from the Statue of Liberty to the US Bank Stadium—home of the Minnesota Vikings—we’ve never looked back. Arconic’s Kawneer, Reynobond and Reynolux technology can be found across skylines the world over.

"Our breakthrough technologies serve a larger purpose—high-thermal performance to meet growing demand for energy efficiency. Resiliency, to protect against hurricanes and natural disasters. And blast mitigation to protect what’s inside—all while advancing the boundaries of architectural design."

In the light of Grenfell this may be cause for some concern!

The company claims to be a very ethical one. It states:

"Arconic is a Values-based company

Our Values guide our behavior at every level and apply across the Company on a global basis. We expect all directors, officers and employees to conduct business in compliance with our Business Conduct Policies and we survey compliance with these policies on an annual basis. The Board has adopted a number of policies to support our values and good corporate governance, which we believe are important to the success of our business and in advancing shareholder interests. Our Corporate Governance Guidelines along with our Certificate of Incorporation, By-Laws, board committee charters, Director Independence Standards, Code of Ethics for the CEO, CFO and Other Financial Professionals and Related Person Transaction Approval Policyform the foundation for the governance of Arconic."

The question to be posed is:

- Does it do all that it realistically can to warn buyers of the limitations of its products as well as its advantages, with all the necessary precautions to be applied?

- More specifically did it do so in the case of the Grenfell Tower refurbishment?

- If it knew of inherent dangers in relation to exterior cladding and fire why did it not insist that fire retardant panel were used?

Structure of an ACM sandwich panel. In the case of Reynobond PE, aluminum sheets' thickness is 0.5 mm (0.020 in) and overall panel thickness is either 3, 4 or 6 mm. https://en.wikipedia.org/wiki/Grenfell_Tower_fire#/media/File:ACP_structure_-_small.png

The precise specification can be found here: http://www.arconic.com/global/en/products/product.asp?prod_id=1706&cat_id=916 (3)

The above diagram may misrepresent the material actually used on Grenfell insofar as the overall depth of the panel we are told was three (3) mm. If so the polypropylene (polythene) filling would be only two (2) mm and proportionately much thinner than that shown.

This does raise the fundamental question:

- why the panels were so innately flammable?

Physical Properties of Aluminium in Fire

As probably most people know, there are three basic requirements for combustion (fire oxygenation) to take place: heat, oxygen and fuel. Although plastic is flammable, aluminium isn't. Aluminium is rated AA for fire resistance. It melts at 660 degrees Centigrade - twice the temperature required to melt lead. It melts but will not burn. See below (1) Although this document (2) gives ranges of 935 to 1215 degrees F. clearly much lower. I am not a metallurgist and so unable to explain this wide divergence in physical properties but it needs to be.

As probably most people know, there are three basic requirements for combustion (fire oxygenation) to take place: heat, oxygen and fuel. Although plastic is flammable, aluminium isn't. Aluminium is rated AA for fire resistance. It melts at 660 degrees Centigrade - twice the temperature required to melt lead. It melts but will not burn. See below (1) Although this document (2) gives ranges of 935 to 1215 degrees F. clearly much lower. I am not a metallurgist and so unable to explain this wide divergence in physical properties but it needs to be.

In practice the compressed laminated nature of the panel would prevent the air (oxygen) getting to the interior polythene layer which in any event at just 2 mm thick, it is hard to see how it would generate so much flame and heat, without some additional physical factor involved.

In addition, aluminium is very good at conducting heat, which would have the effect of reducing surface temperature, yet this appears to have had no mitigating effect, the fire raging white hot and emitting grey coloured smoke suggestive of the aluminium itself being consumed. This is quite extraordinary and proves the temperature of the blaze must have been in excess of 660 degrees at least.

The basic questions to be answered therefore are:

- What was the melting point of the aluminium alloy panel actually used?

- How was it possible given the laminated construction denying air access to the flammable polythene core, was such an intense fire allowed to take hold?

- Given the fact that aluminium melts but does not burn and only a relatively thin (2 mm) of inflammable plastic was available to support combustion, how can the intense heat, white-hot flame, white smoke and incredible speed of spread, be explained?

- Was the aluminium material used for these specific panels altered in any way to support combustion?

All this information should already be available to investigators if urgent tests have been carried out under controlled conditions, as of course they should have been.

The refurbishing scheme was supervised by Studio E Architects, based at http://www.studioe.co.uk/?page_id=997 As such this firm would carry the ultimate responsibility for the specification and standard of work.

The schemes in which the firm has been involved are listed on its web site. They appear to be predominantly social and educational, many benefiting from Government policy and grants. A photograph of the Grenfell building on completion and prior to the fire, is still featured on the firms web page (as of 21.6.2017)

Over 120 clients are listed including many related to central and local government, particularly in the capital.

Directors:

Andrzej Kuszell

DIRECTOR

RIBA, DipArch

Andrzej Kuszell is a Founding Director of Studio E Architects. His main drive has been to develop and raise the practice’s architectural profile with a particular focus in education and sports/leisure design. With a passion for surpassing his clients’ expectations, he has become a recognized innovator in both sectors with results founded on a commitment to holistic sustainability, collaborative teamwork and a recognition that every project is special.

Responsible for a succession of award winning projects, these have included a range of new buildings at Haileybury College, the aspirational Leisure Centre for the American Community School in Cobham, the green exemplar Larmenier and Sacred Heart Primary School and the City of London Academy, Southwark which won the 2006 Prime Minister’s Better Public Building Award. In the last 6 years Andrzej has taken the lead in the design of five new Academies, two new Primary Schools as well as new International Schools in the Middle East. These projects included the City Academy, Hackney which won the BCSE Best Academy Award as well as the recently completed Kensington Aldridge Academy. In the same period the practice has twice won the BCSE School Architect of the Year Award.

David Lloyd Jones

DIRECTOR

Beside much other work and clients we are informed that:

"Rydon has been working with the MoD for several years as a partner on the Aspire Defence Capital Works through the Allenby/Connaught framework, the largest infrastructure Private Finance Initiative project ever let by the Ministry of Defence.

"Our role has been to support Aspire Defence in the modernisation and reprovision of a significant number of military facilities around Salisbury Plain.

"To date, Rydon has won in excess of £50m of work across over 25 projects through the framework, all of which have been delivered on live operational military bases."

A chosen contractor for works is not responsible for the design of the scheme, only the competent implementation of it.

DIRECTOR

FRSA, RIBA, AA DIPL

David is a Founding Director of Studio E Architects. An acknowledged expert and innovator in energy conscious and sustainable architecture he is responsible for a body of research work and publications that have informed Studio E Architects projects across the board. He has led on a sequence of award winning sustainable projects across a range of sectors. These have included Doxford International Solar Office, the Beaufort Zero Emissions Building, Grange Park Opera House and Townley Grammar School for Girls. Recent work has extended to master planning of the City of London Freemen’s School, the refurbishment of Highgrove Pool, designs for a new sports pavilion at Hackney Marshes and proposals for a new Arts and Crafts Institute in Pakistan. He overviews the practice’s QMS and drives the practice’s policies for high achievement in sound, energy conscious environmental design

GRENFELL TOWER – STUDIO E ARCHITECTS STATEMENT

We are deeply shocked and distressed over news of the devastating fire at Grenfell Tower. Our thoughts are with those that have been affected by this tragic incident, together with all of their relatives and friends. It would be inappropriate for us to comment or speculate on events on Wednesday morning. We will be available to assist the relevant authorities as and when we are required. Our website was temporarily shut down yesterday as a result of the number of requests received.

In contrast an earlier happier story:

"HRH THE DUCHESS OF CAMBRIDGE OPENS KENSINGTON ACADEMY AND LEISURE CENTRE

"Transformational new school and leisure centre receive Royal stamp of approval!

"On Monday 19th January 2015 Kensington Aldridge Academy, together with the Kensington Leisure Centre, received a Royal Opening. A special moment for this corner of North Kensington after 3 years of design and construction. Studio E Architects were the master plan lead for the entire project and architects for the Academy."

The critical questions that presumably have been posed of the architects will have been:

- Did you specify the materials and fixing method of the external cladding in particular?

- Did you supervise its installation and sign off on the work?

- Were you satisfied that in all respects the work was completed in accordance with the specification?

- As respects to the interior upgrading, did you make any recommendations to the clients (the Royal Borough of Kensington or Tenant Management Organisation) on matters of fire or general safety, and if so were they all adopted?

- On completion of the works did you have any further dealings with the clients with regard to the building specifically regarding tenants representations on safety or the satisfactory nature of the works and if so what?

Main Contractor

The firm primarily responsible for carrying out the work was Rydans Construction based in Essex. Their web site is here: http://www.rydon.co.uk/who-we-are

It states:

It states:

"From our beginnings in 1978, Rydon has grown into a multi-faceted company, employing over 750 people.Rydon delivers quality solutions in the built environment for education, housing and healthcare to shape and advance people’s lives."

"Rydon has been working with the MoD for several years as a partner on the Aspire Defence Capital Works through the Allenby/Connaught framework, the largest infrastructure Private Finance Initiative project ever let by the Ministry of Defence.

"Our role has been to support Aspire Defence in the modernisation and reprovision of a significant number of military facilities around Salisbury Plain.

"To date, Rydon has won in excess of £50m of work across over 25 projects through the framework, all of which have been delivered on live operational military bases."

A chosen contractor for works is not responsible for the design of the scheme, only the competent implementation of it.

The question for the main contractor therefore must be:

- Did you carry out the works in complete accordance with the plans and specification or did you alter any of them in respect of either the materials used or the way in which they were applied?

- Did you at any stage have any reservations concerning these or make any representations concerning any matters that impinged on safety and particularly fire safety?

Cladding Contractors

The actual cladding work was carried by Harley Facades Ltd. The company's web site is here: http://www.harleyfacades.co.uk/ This element of the refurbishment was contracted for £2.3 m.

The web site states:

The web site states:

"Harley Facades Ltd provides a comprehensive design and construction package for building envelopes including; curtain walling, windows, doors, structural glazing, and rainscreen cladding systems. Incorporating curtain walling and rainscreen into your concept design, can create a unique and cost effective solution for your building. Curtain walling and rainscreen is suitable for both new build and refurbishment projects. Harley Facades Limited has successfully undertaken projects throughout the UK involving curtain walling and rainscreen."

"Owner and Managing Director, Ray Bailey, formed the original Harley business in 1996. With a move to it's own brand new purpose built offices in December 2003, Harley had now become well established as one of the leaders in the field of designing and constructing complete building envelopes. A further development came with the formation of Harley Facades Ltd, a business to focus on the specialist refurbishment market including high rise residential tower blocks."

GRENFELL TOWER FIRE STATEMENT FROM HARLEY FACADES LTD

"Harley Facades Limited completed the refurbishment work to Grenfell Tower. This included the installation of exterior cladding. The Aluminium Composite Material (ACM) panels are a commonly used product in the refurbishment industry. Harley Facades Limited do not manufacture these panels.

"Commenting on the fire, Ray Bailey, Managing Director at Harley Facades Limited said:

“This is an incredibly tragic incident. Our thoughts are with the residents and their families who have suffered such a personal loss. We will fully support and cooperate with the investigations into this fire. There will be many questions about this whole incident and so you will appreciate that it would not be appropriate for us to comment or for others to speculate on any aspect of fire or it causes in advance of these inquiries. At this time, we are not aware of any link between the fire and the exterior cladding to the tower.”

Ventilation Contractor

Apparently ventilation works were carried out. This has a baring on the disaster because the objective is to provide sufficient ventilation in case of fire to at least keep the access/escape stairway free of smoke. I am not party to what work was carried out not how far the ventilation secured this objective. All we have are numerous witness statements to the effect that the common areas and staircase was in fact with smoke and fume.

Apparently Witt UK was chosen for this part of the refurbishment. On its web site here, http://wittukgroup.co.uk/fan-systems/ which it is claimed was taken down immediately after the event, it states:

"Fan Systems was founded in 1950, and is an acknowledged leader in the manufacture of high quality industrial fans, with units operating across a diverse range of process applications throughout the world.

"Fan Systems became part of the WITT UK Group in 1993, and acquired Alldays Peacock in 2006, adding high pressure blowers and gas boosters to complement its extensive fan range.

"Now operating from an exceptional new site in Yorkshire, and with additional world wide manufacturing capability, Fan Systems Group has one of the most advanced fan production facilities."

Question:

- As a specialist area, the design brief came from where and who approved it?

- Did the ventilation system work as intended, was the design defective or did it fail in some other manner?

Other specialist firms were employed to deal with the up-grading of electrical and other services inside the block that may have had implications on the way the incident spread and was alarmed but these are not touched on in this article. Readers are also referred to earlier articles on the subject on this blog.

REFERENCES

1. Extract from: http://www.alfed.org.uk/files/Fact%20sheets/11-aluminium-and-fire.pdf

"Aluminium in a Fire If aluminium is involved in a fire and the temperature rises to above its melting point, the metal begins to melt. The melting point of a metal, like its density, strength, or corrosion resistance, is a characteristic which can be measured and used to design the most effective component for any particular application. The thermal conductivity of aluminium is around four times that of steel and its specific heat twice that of steel. This means that heat is conducted away faster and a greater heat input is necessary to bring the same mass of aluminium to a given temperature, compared with steel. Where an aluminium structure is exposed to the heat of a fire, the relatively high thermal conductivity enables the heat to be rapidly conducted away from the exposed area. This helps to reduce hot spots where significant localised property loss could occur, so extending the serviceability period. It will, however, cause the temperature to rise elsewhere. The extent of dissipation of heat elsewhere in the structure will depend on the degree of thermal insulation provided to the aluminium elsewhere in the structure, necessary to provide fire protection in that area.

Relectivity of aluminium is 80% to 90%, compared with 5% for painted steel and 25% for stainless steel. This is of considerable benefit and will assist in prolonging endurance of an aluminium structure in a fire. The attached photograph is a good example of the behaviour of aluminium in the massive form in a fire. A car, with aluminium alloy wheels, was caught in a forest fire that swept over the car and moved on. Afterwards it was found that the aluminium wheels had melted, molten aluminium had run off and collected in a pool of metal which solidified as the fire moved on and the temperature fell. The aluminium had not burnt. "

"Aluminium alloy components are widely used in building as cladding and roofing materials, windows and doors. As defined by BS 476: Part 4 and the 1974 SOLAS Convention (as amended) aluminium alloys are ‘non-combustible’ and also provide Class 1 surface spread of flame to BS 476: Part 7. In addition, BS 476: Part 3 covers external fire exposure roof tests and the classifications laid down in the standard range from AA to DD. The first letter refers to the fire penetration performance and the second letter to the surface spread of flame. Aluminium and its alloys are rated AA, the highest possible under this classification system. Materials are also tested for fire propagation performance to BS 476: Part 6 (1989) and coating systems are taken into account. Aluminium achieves excellent ratings under this Standard."

SEE ALSO: http://www.alfed.org.uk/files/Fact%20sheets/11-aluminium-and-fire.pdf

2. https://www.unitedaluminum.com/chemical-composition-and-properties-of-aluminum-alloys/

3. http://www.arconic.com/global/en/products/product.asp?prod_id=1706&cat_id=916

4. https://en.wikipedia.org/wiki/Grenfell_Tower_fire

REFERENCES

1. Extract from: http://www.alfed.org.uk/files/Fact%20sheets/11-aluminium-and-fire.pdf

"Aluminium in a Fire If aluminium is involved in a fire and the temperature rises to above its melting point, the metal begins to melt. The melting point of a metal, like its density, strength, or corrosion resistance, is a characteristic which can be measured and used to design the most effective component for any particular application. The thermal conductivity of aluminium is around four times that of steel and its specific heat twice that of steel. This means that heat is conducted away faster and a greater heat input is necessary to bring the same mass of aluminium to a given temperature, compared with steel. Where an aluminium structure is exposed to the heat of a fire, the relatively high thermal conductivity enables the heat to be rapidly conducted away from the exposed area. This helps to reduce hot spots where significant localised property loss could occur, so extending the serviceability period. It will, however, cause the temperature to rise elsewhere. The extent of dissipation of heat elsewhere in the structure will depend on the degree of thermal insulation provided to the aluminium elsewhere in the structure, necessary to provide fire protection in that area.

Relectivity of aluminium is 80% to 90%, compared with 5% for painted steel and 25% for stainless steel. This is of considerable benefit and will assist in prolonging endurance of an aluminium structure in a fire. The attached photograph is a good example of the behaviour of aluminium in the massive form in a fire. A car, with aluminium alloy wheels, was caught in a forest fire that swept over the car and moved on. Afterwards it was found that the aluminium wheels had melted, molten aluminium had run off and collected in a pool of metal which solidified as the fire moved on and the temperature fell. The aluminium had not burnt. "

"Aluminium alloy components are widely used in building as cladding and roofing materials, windows and doors. As defined by BS 476: Part 4 and the 1974 SOLAS Convention (as amended) aluminium alloys are ‘non-combustible’ and also provide Class 1 surface spread of flame to BS 476: Part 7. In addition, BS 476: Part 3 covers external fire exposure roof tests and the classifications laid down in the standard range from AA to DD. The first letter refers to the fire penetration performance and the second letter to the surface spread of flame. Aluminium and its alloys are rated AA, the highest possible under this classification system. Materials are also tested for fire propagation performance to BS 476: Part 6 (1989) and coating systems are taken into account. Aluminium achieves excellent ratings under this Standard."

SEE ALSO: http://www.alfed.org.uk/files/Fact%20sheets/11-aluminium-and-fire.pdf

2. https://www.unitedaluminum.com/chemical-composition-and-properties-of-aluminum-alloys/

3. http://www.arconic.com/global/en/products/product.asp?prod_id=1706&cat_id=916

4. https://en.wikipedia.org/wiki/Grenfell_Tower_fire

Ross Cowan my goodness sir! did i ever say Thank you for your blog? IT's like having the Best of.. analysis delivered right to the Forest door. Amazing gift you have.. and always objective.. much respect Tim

ReplyDeleteLike · Reply · 1 hr

Remove

Ross Cowan

Ross Cowan when was the cladding placed and does the timing coincide at all with the victim website count as Ian mentioned?

Like · Reply · 52 mins

Remove

Tim Veater

Tim Veater Ross Cowan The renovations were completed/signed off just one year before in 2016. Wikipedia states only five bodies have been identified and 74 persons are not accounted for presumed dead, giving the total of 79. (Note stark contrast with recent suicide bombers who are identified immediately with aid of their undamaged documentation!) However the figure of 79 appears quite unrealistic given the number - between 5 and 600 - that were assumed to be in the building at the time. I think Ian, reflecting the view of the UK Column, is right when he asserts something is very wrong about the way the issue of fatalities has been handled by government and media.

Like · Reply · 1 · 23 mins

Edit

Tim Veater

Tim Veater Ross Cowan Many thanks Ross. We can but try!

Like · Reply · 1 · 21 mins

Edit

Ross Cowan

Ross Cowan Tim Veater there was a link, i can find above, of a victim count link. dated prior.. i was wondering of those two dates shared a commonality. and quite right.. about the immediate recognition of those " moose limb terrorists with the ever indestructible id

Like · Reply · 1 · 20 mins

Remove

Ross Cowan

Ross Cowan Tim Veater your efforts gallant and noble, your thinking clinical and precise and objective, never a rude word, always humble and polite. spreading knowledge and peace in the forest.. I bow .

Like · Reply · 19 mins

Remove

Tim Veater

Tim Veater Ross Cowan I have some real reservations about the fire it must be said. First there are, as we have grown to expect, all the strange co-incidences and weird allusions to 9/11, the most recent the apparent reinsurance of the building. Then the claimed initial cause - the "exploding" fridge - and the fact that no attempt was made to extinguish fire at source and the packed luggage, compounded by the official statement that the source of the fire was not yet determined. Then the ferocity of the blaze sufficient to melt aluminium from just 2mm of laminated polythene. Note this was the ONLY flammable material present yet sufficient to create white smoke and white hot flame. It leads me to question whether there was in fact some additional flammable element incorporated in the panels? This could only happen I believe if there was criminal intent of a very profound sort at the factory stage which seems highly unlikely. But then we have had 9/11 haven't we?

Like · Reply · 2 mins · Edited

Edit

Tim Veater

Tim Veater Ross Cowan Too kind I'm sure Ross but thanks anyway. xx

Like · Reply · 3 mins

Edit

Tim Veater

Tim Veater I am reluctant to say the word .... thermite?

Like · Reply · Just now

Edit

Ross Cowan

Ross Cowan not kind at all , its a clinical approach and its a gentlemanly approach i find refreshing, and of course the shame i feel in my own prose... my mother would not approve of my writing at this point, yours is impeccable. the lyricists the wordsmiths, the analysts among the Frogs astounds me.. and of course you are most welcome friend. as Odenmark would say " hat doffed". i would give " Wai".. excellent sir

Ross Cowan Tim Veater thermate is the military application and you just took that one of way deep in left field.. perhaps.. the question in my mind is also: 2 many died or not enough,, and where are the bodies and families.. besides a few drummed up.. how many pounds would that take? nice relocation job.. you piqued my interest.. the game is afoot. Dr.

ReplyDeleteLike · Reply · 20 mins

Remove

Ross Cowan

Ross Cowan though i think thermate would have cut the steel quickly , its not made for this.. the tower stood

Like · Reply · 19 mins

Remove

Ross Cowan

Ross Cowan the plastic upgrade seems at heart

Like · Reply · 18 mins

Remove

Tim Veater

Tim Veater Of course thermite is a largely aluminium based alloy. mmmmm?

Like · Reply · 1 · 17 mins

Edit

Ross Cowan

Ross Cowan Tim Veater the SO2 is the oxidizing agent..over here i would recommend following immediate knee jerk legislation or navy moves, as well as timing , and events that should not have occurred in the absence of an underlying connection.. was the building condemned or in process of such as twin towers, the insurance timing, Gibbs rule 39 applies to nursing as well..

Like · Reply · 12 mins

Remove

Tim Veater

Tim Veater Ross Cowan I hope you don't mind but I have added this converation to the comments section of my blog as it raises some interesting points. If you have any objections I will remove it immediately.

Like · Reply · Just now

Edit

Tim Veater

Write a reply...

Choose File

Tim Veater

Tim Veater Ross I am reluctant to point out, you may consider I am being a trifle arrogant, but Grenfell is a completely different form of construction to WTC. The latter was all steel members which were severed using probably high grade military thermite or similar, possibly in combination with other explosive devices. Glenfell on the other hand is a reinforced concrete structure which can withstand great temperature without weakening (not unlike steel of course) But the demolition method would not employ thermite which, as far as I am aware, only reacts with and cuts through, steel. In the case of Grenfell what we are dealing with is not structure but external cladding which burned with a great intensity never before witnessed by professional fire fighters of long standing. So what if in the manufacturing process, either by accident or design - and I have no idea if it would be possible - some form of thermite like composite was created in the aluminium used to make the panels? Far fetched I know but if the laminated polythene was insufficient to create the type of conflagration observed, some alternative explanation would have to be proposed. Of course tests on the remaining panels, if carried out honestly, should provide an immediate answer.

This comment has been removed by the author.

ReplyDelete600 Tower Blocks with cladding. How many flammable? What a WASTE of resources in the past? Grenfell Tower panels proved to be flammable. What a balls-up! Nicholas Holgate, RB of Kensington Chief Executive, effectively told to resign by communities secretary, Sajid Javid on Tuesday the Mail reported.

ReplyDeleteWhy is there absolutely NOTHING regarding the criminal investigation? Who is doing it? What resources are given to it? What are the methods and priorities? And why no detailed information on the number of bodies recovered or persons in the building not located?

ReplyDeleteRe-insurance bill from 25 million to a billion????? Why? Norway firm to meet the cost? https://www.youtube.com/watch?v=2muOH2CHXbM

ReplyDeleteMelbourne Australia's Con Capital. For some time now, Melbourne appears thave been the foci of deep state/espionage activity centred around Monash University and the jewish community there, ever since the Ben Zygier incident. https://en.wikipedia.org/wiki/John_Monash. http://www.abc.net.au/news/2013-02-12/australia-suspected-of-mossad-links-dies-in-israeli-jail/4514806 Notice how yet again western states copy cat, even down to the size and shape of concrete blocks, supposedly for pedestrian safety after Melbourne had its own ridiculous 'drive-by'. Nor should we overlook the rather strange coincidence that prior to the Grenfell Tower fire, a very similar event occurred in where? Well Melbourne of course. In November 2014 the Melbourne docklands 'Lacrosse' building caught fire. It was supposedly started with just "a cigarrette' and raced up 13 floors. Fortunately no one was killed. Two years later the same material was used for Grenfell Tower with the disastrous consequences we have witnessed. Not a dry run surely? See: https://www.theguardian.com/uk-news/2017/jun/15/cladding-in-2014-melbourne-high-rise-blaze-also-used-in-grenfell-tower

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteRe. Grenfell:

ReplyDeleteNot only was the cladding at Grenfell (and another 120 blocks apparently) 'non-compliant', it was also (according to the Times) unpaid for! The company that purchased it went bust and the over £400 000 bill was never paid. Thing is, a re-named company was immediately set up run by the same man, using the very same panels. So not only fire and deaths require investigation!

Much attention has focused on the absence of sprinklers in blocks of flats. Of course this is only one element in the fire safety regime of a building. Portable extinguishers, hydrants, non-flammable materials, fire doors, ventilation systems, fire protected routes, alarms, appropriate instructions and training, safe equipment and practices all play a part in an integrated system.

That 100% of so many flats have failed flammability tests and Building Regulation requirements, proves Grenfell was not an isolated incidence, although the fire thankfully was - well almost.

This is obviously a major breakdown in the application and enforcement of safety laws on the back of a trend to improve appearance and energy consumption, the responsibility for which rests with manufacturers, specifiers, installers and enforcers in addition to building owners and managers.

One of the issues in the Grenfell case is why it was not possible to extinguish, what was described as a "small fire" before it took hold of the flat and subsequently the exterior cladding?

If suitable fire extinguisers had been provided in the flat or in the common areas, this might have been quite feasible. Reference has been made to extinguishers "being out of date" so we must assume there were some in the building, whilst others say there were none.

This is a critical question that requires an answer. Was it an absence of equipment or an inability on the part of the occupant that resulted in the fire not being extinguished early on?

In a former life in a safety role, I had to fight a plan to remove extinguishers from blocks of flats owned by a Housing Association. Their removal was seen by management as an easy cost-saving measure.

Unfortunately even technically qualified professionals sometimes fail to see the importance of basic safety measures, which by definition may never be employed, but if needed may prevent a huge disaster both in terms of cost and human life.

A very thorough Sky investigation published on You Tube on the 22nd June, 2017. (Note date!) The programme must have been completed within seven days of the event. It should be noted that the Sun, also part of the Murdoch empire, by strange coincidence, had what appears to have had a pre prepared article on the 22.5.2017 - the very day of the Manchester attack - specifically linking Corbyn to IRA terrorism, and this before the up-coming election.

ReplyDeletehttps://www.thesun.co.uk/news/3623936/jeremy-corbyn-might-not-have-planted-a-bomb-but-he-made-it-easier-for-those-who-did-says-former-ira-man/

Very little attention has been paid to the initial fire. It has been reported this was caused by an "exploding" fridge/freezer in flat 16 on the fourth floor. Are these numbers significant or purely random? 4 x 16 = 64. 4 x 4 = 16 x 4 = 64. We are told it is the number of generations from Adam until Jesus according to the Gospel of Luke. Also The mathematician W. R. Ball reports a legend 64 discs of gold of different sizes piled one on top of the other to create the 'Tower of Brahma'. When the 64 discs will be transferred from the tower of Braham to an other stem, the temple and the Universe will crumble. This will be the end of the world. There are 64 squares of a game of chessboard. Strangely 64 Free Masons have been awarded the VC for extreme bravery and a memorial to them was opened by the Duke of Kent in London on the 25th April, 2017. There are 64 best images of Masonic buildings here: https://uk.pinterest.com/dariuszprokicki/masonic-buildings-details/

ReplyDeleteHere is one of them: https://uk.pinterest.com/pin/432486370444202452/

Washington Monument Commemorative Stone: Masons, Lafayette Lodge No. 64, New York City. 64 Key West 909 Fleming St KEY WEST FL 33041-1248 The United Grand Lodge of England is celebrating its 300th Anniversary. The ‘Rough to Smooth: Art inspired by Freemasonry – past, present and future’ exhibition will open at Freemasons’ Hall on Saturday 24th June 2017 and will run until 1st July (7 days) https://www.youtube.com/watch?v=jwZms6GpyO8 "Interpreting metaphor."

Of course numerical coincidences have no significance to the Grenfell disaster.

Details have been given of the make and model but no explanation given as to what may have caused the explosion or how it took hold.

Wherever an "explosion" has been referred to, should not this require special attention?

There were of course TWO different materials attached to the exterior. We seem to hear only of the aluminimum panels.

ReplyDeleteGreat information about the fire hazards and the per-measures to be taken to escape form the fire doors.

Fire rated doors dealers in Bangalore